4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE is a leading brand recognized for its innovation in the design and manufacture of tool changing spindles for the manufacturing industry. These spindles are vital components in a wide range of industrial applications, from the automotive and aerospace industries to consumer product manufacturing.

Tool Changing Spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE are distinguished by their ability to quickly change between different tools, increasing efficiency and productivity in high-speed manufacturing environments. This rapid and precise tool change allows agile adaptation to different production needs, resulting in reduced downtime and greater flexibility.

The advanced technology used in the manufacturing of these spindles ensures optimal performance and long life. 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE focuses on precision and reliability to ensure trouble-free operation in various manufacturing settings. Additionally, its focus on innovation has resulted in compact, efficient designs that take up minimal space on production lines.

These tool changing spindles are highly adaptable and can be integrated with a variety of machine tools and control systems. This allows them to be used in a wide range of processes, such as milling, turning, drilling and grinding, among others. The ability to quickly change tooling ensures greater versatility in production, allowing manufacturers to diversify their product range and optimize their manufacturing processes.

Additionally, customization capability is a prominent feature for spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, the company works closely with customers to understand their needs. and provide solutions tailored to your particular applications. This ability to adapt and customize places 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE in a prominent position in the tool changing spindle market.

In conclusion, tool changing spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE represent a significant advance in manufacturing automation and efficiency. Their ability to quickly switch between tools, along with their reliability and precision, make them a preferred choice for companies looking to optimize their production operations. With a focus on quality and innovation, 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE continues to serve as a trusted partner for the improvement of manufacturing processes globally.

The elements that make up this category of products are the following:

ELEMENTS

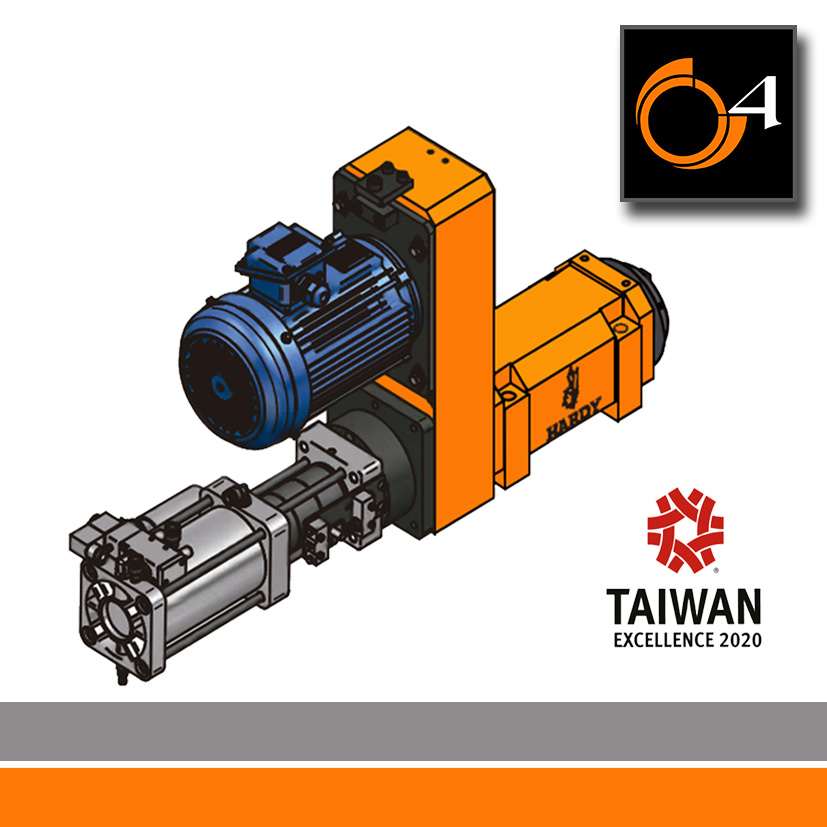

SC Series

SQUARE HOUSING MILLING/BORING HEADS AND REAR PNEUMATIC PISTON FOR AUTOMATIC TOOL CHANGE

- SC55-BT40

- Spindle Capacity: BT40

- Maximum Speed: 2,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SC55H-BT40

- Spindle Capacity: BT40

- Maximum Speed:6,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SC80-BT50

- Spindle Capacity: BT50

- Maximum Speed: 1,200 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

- SC80H-BT50

- Spindle Capacity: BT50

- Maximum Speed:3,000 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

SCS Series

SQUARE HOUSING MILLING/BORING HEADS AND SIDE PNEUMATIC PISTON FOR AUTOMATIC TOOL CHANGE

- SCS55-BT40

- Spindle Capacity: BT40

- Maximum Speed: 2,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SCS55H-BT40

- Spindle Capacity: BT40

- Maximum Speed:6,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SCS80-BT50

- Spindle Capacity: BT50

- Maximum Speed: 1,200 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

- SCS80H-BT50

- Spindle Capacity: BT50

- Maximum Speed:3,000 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

Tool Changing Spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE are distinguished by their ability to quickly change between different tools, increasing efficiency and productivity in high-speed manufacturing environments. This rapid and precise tool change allows agile adaptation to different production needs, resulting in reduced downtime and greater flexibility.

The advanced technology used in the manufacturing of these spindles ensures optimal performance and long life. 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE focuses on precision and reliability to ensure trouble-free operation in various manufacturing settings. Additionally, its focus on innovation has resulted in compact, efficient designs that take up minimal space on production lines.

These tool changing spindles are highly adaptable and can be integrated with a variety of machine tools and control systems. This allows them to be used in a wide range of processes, such as milling, turning, drilling and grinding, among others. The ability to quickly change tooling ensures greater versatility in production, allowing manufacturers to diversify their product range and optimize their manufacturing processes.

Additionally, customization capability is a prominent feature of spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, the company works closely with customers to understand their needs. and provide solutions tailored to your particular applications. This ability to adapt and customize places 4ManPro® (Elements For Manufacturing Processes) Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE in a prominent position in the tool changing spindle market.

In conclusion, tool changing spindles from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE represent a significant advance in manufacturing automation and efficiency. Their ability to quickly switch between tools, along with their reliability and precision, make them a preferred choice for companies looking to optimize their production operations. With a focus on quality and innovation, 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE continues to serve as a trusted partner for the improvement of manufacturing processes globally.

The elements that make up this category of products are the following:

ELEMENTS

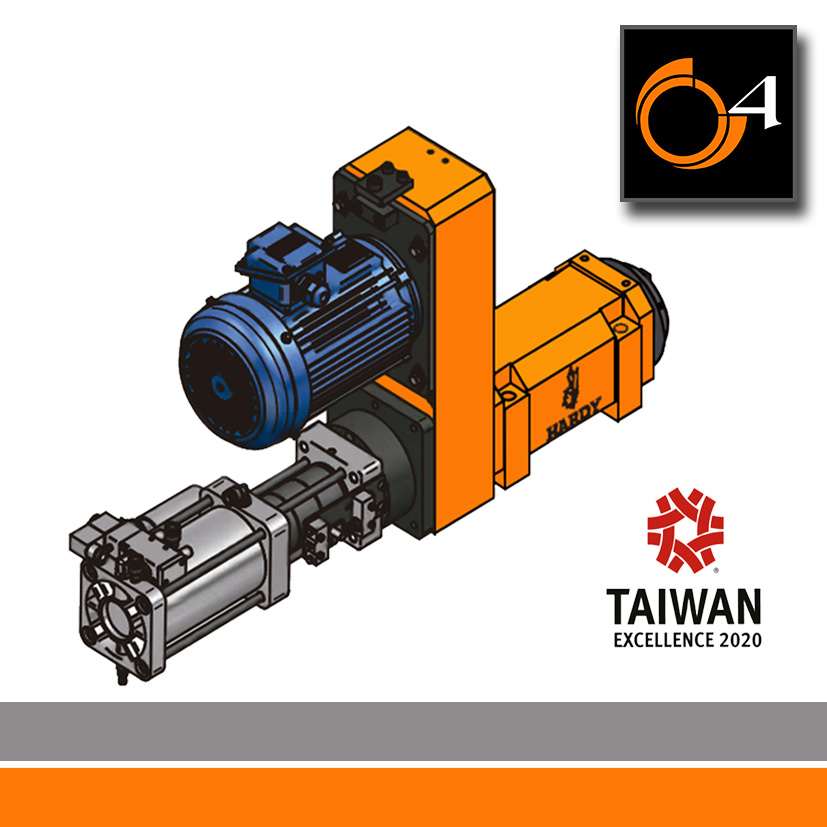

SC Series

SQUARE HOUSING MILLING/BORING HEADS AND REAR PNEUMATIC PISTON FOR AUTOMATIC TOOL CHANGE

- SC55-BT40

- Spindle Capacity: BT40

- Maximum Speed: 2,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SC55H-BT40

- Spindle Capacity: BT40

- Maximum Speed:6,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SC80-BT50

- Spindle Capacity: BT50

- Maximum Speed: 1,200 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

- SC80H-BT50

- Spindle Capacity: BT50

- Velocidad Máxima:3,000 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

SCS Series

SQUARE HOUSING MILLING/BORING HEADS AND SIDE PNEUMATIC PISTON FOR AUTOMATIC TOOL CHANGE

- SCS55-BT40

- Spindle Capacity: BT40

- Maximum Speed: 2,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SCS55H-BT40

- Spindle Capacity: BT40

- Maximum Speed:6,000 r.p.m.

- Maximum Power: 2 H.P. ~ 3 H.P.

- SCS80-BT50

- Spindle Capacity: BT50

- Maximum Speed: 1,200 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.

- SCS80H-BT50

- Spindle Capacity: BT50

- Maximum Speed:3,000 r.p.m.

- Maximum Power: 3 H.P. ~ 5 H.P.