4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, is a leading manufacturer of counterboring heads, offering high-quality products designed to optimize efficiency and precision in manufacturing processes. manufacturing. Countering heads manufactured by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, are recognized for their high reliability and exceptional performance in demanding production environments.

These heads are used in a variety of applications, from the automotive to aerospace industries, and are designed to work with a wide range of materials, including metals, plastics and composites. The versatility of countersigning heads from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, makes them ideal for implementation in various production lines.

The advanced technology used in the manufacturing of these heads ensures high precision and long life. Rigorous quality control processes ensure that each head meets the highest standards of performance and durability. Additionally, 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, offers customization services to meet specific customer needs, including custom design and custom manufacturing capabilities. .

Efficiency is a fundamental pillar of countering heads from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE. Thanks to their innovative design and the incorporation of the latest technologies, these heads increase productivity and reduce downtime in manufacturing operations. This translates into increased profitability and a significant improvement in production processes.

In summary, countersigning heads manufactured by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, are an excellent choice for companies looking to maximize efficiency, quality and profitability in your manufacturing operations. With its focus on innovation and excellence, 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, continues to be a leader in the development of world-class countersigning solutions for the global manufacturing industry.

The ELEMENTS included in this section include the following:

ELEMENTS

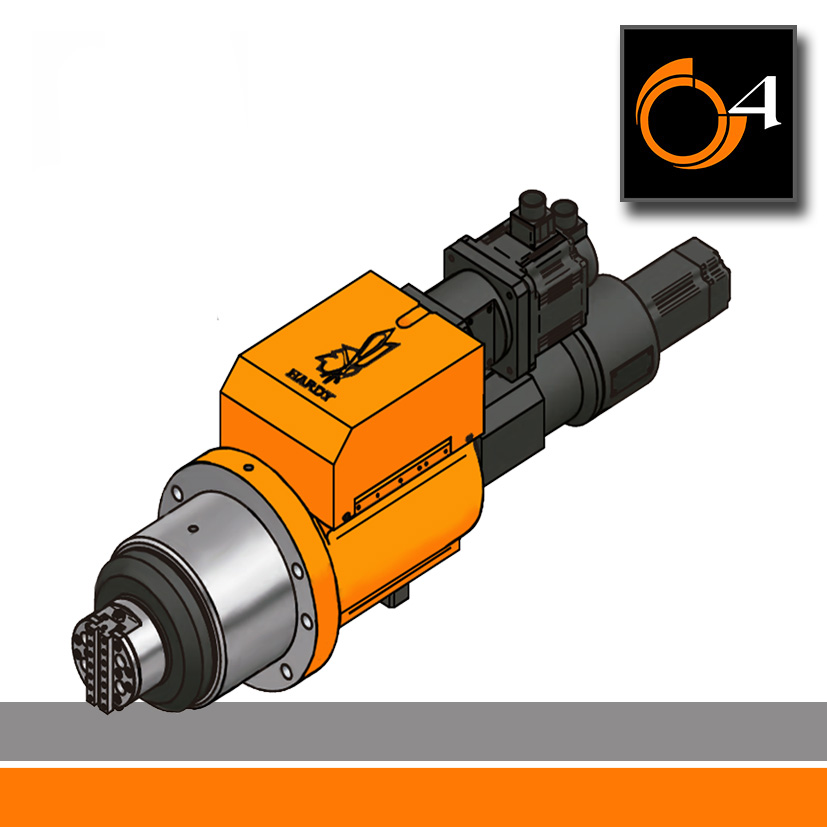

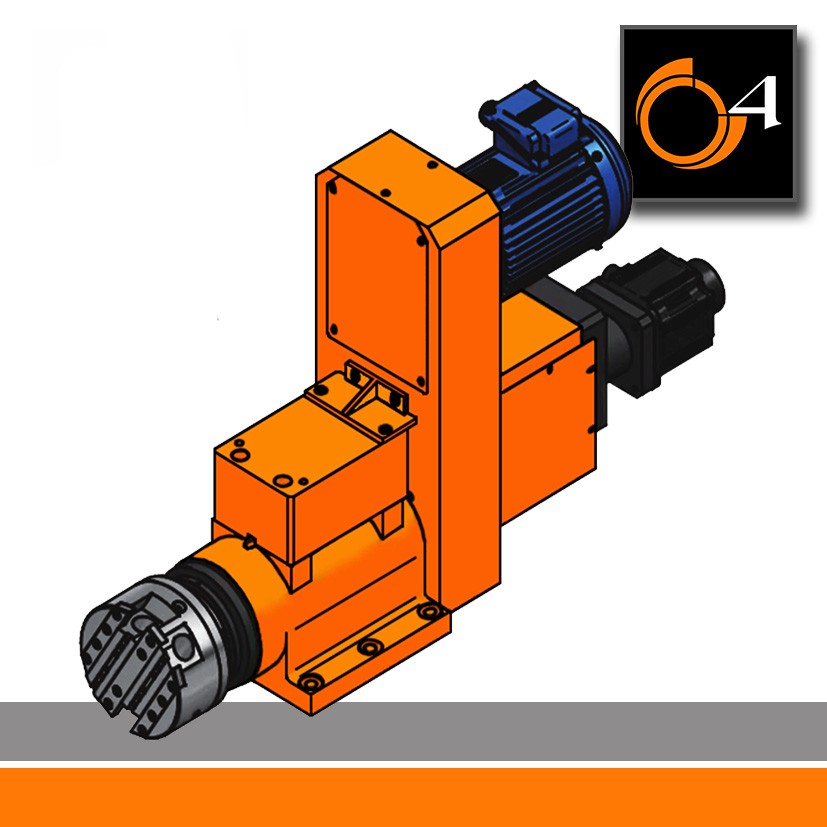

FMDM SERIES

COMPACT SERVO HEAD FOR FACING

- FMDM155-FA408

- MAXIMUM SPINDLE STROKE: 120.00 mm.

- MAXIMUM SPEED: 1,600 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 3.7 Kw.

- FACING HEAD MODEL: FA-408

- MAXIMUM LATERAL STROKE: 8.00 mm.

*** Device EQUIPPED With Oil Cooling Capability.

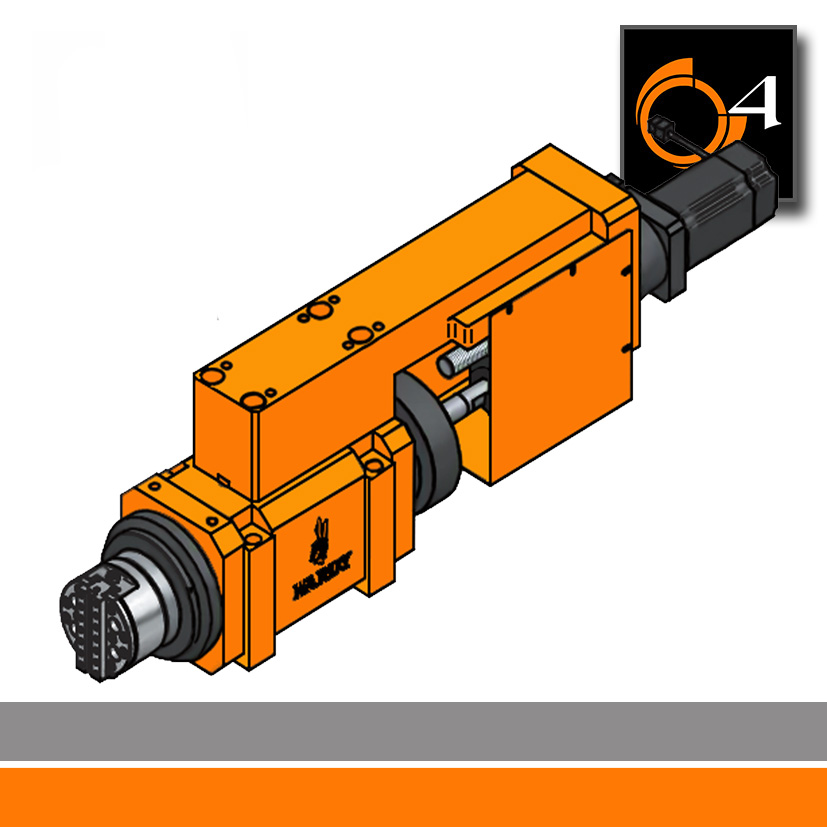

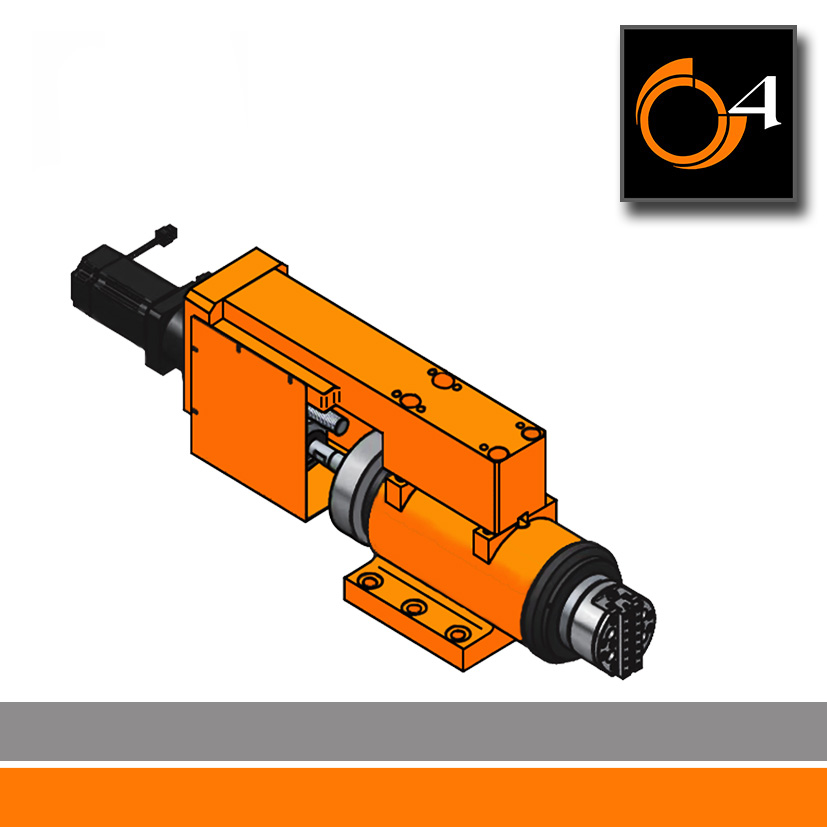

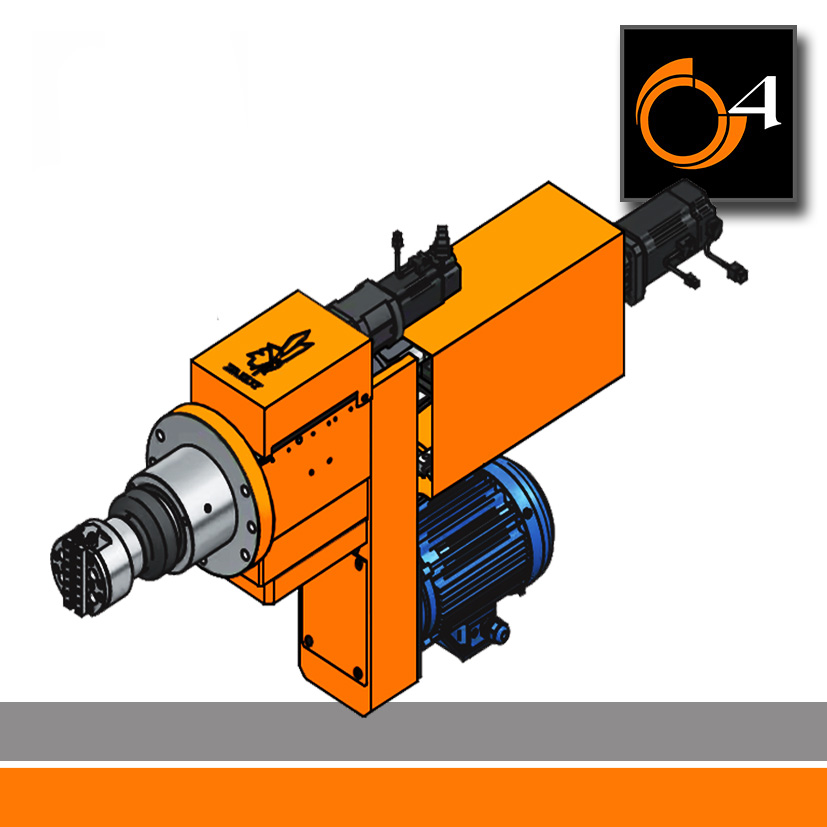

S-F / SR-F SERIES

SERVO SPINDLES FOR FACING

- S60-A2-4 (F408)

- MAXIMUM SPINDLE TURNING SPEED: 1,600.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 2.00 H.P. x 4P

- FACING HEAD MODEL: FA-408

- MAXIMUM LATERAL STROKE: 8.00 mm.

- SR60-A2-4 (F408)

- MAXIMUM SPINDLE TURNING SPEED: 1,600 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 2.00 H.P. x 4P

- FACING HEAD MODEL: FA-408

- MAXIMUM LATERAL STROKE: 8.00 mm.

- S60-A2-4 (F610)

- MAXIMUM SPINDLE TURNING SPEED: 1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 2.00 H.P. x 4P

- FACING HEAD MODEL: FA-610

- MAXIMUM LATERAL STROKE: 10.00 mm.

- SR60-A2-4 (F610)

- MAXIMUM SPINDLE TURNING SPEED: 1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 2.00 H.P. x 4P

- FACING HEAD MODEL: FA-610

- MAXIMUM LATERAL STROKE: 10.00 mm.

- S80-A2-5 (FA812)

- MAXIMUM SPINDLE TURNING SPEED:

- 800.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 2.00 H.P. x 4P

- FACING HEAD MODEL:

- FA-812

- MAXIMUM LATERAL STROKE:

- 12.00 m:

- MAXIMUM SPINDLE TURNING SPEED:

- S80-A2-5 (FD880)

- MAXIMUM SPINDLE TURNING SPEED:

- 1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 3.00 H.P. x 4P

- FACING HEAD MODEL:

- FD-880 (DOUBLE SLIDE TYPE)

- MAXIMUM LATERAL STROKE:

- 80.00 mm.

- MAXIMUM SPINDLE TURNING SPEED:

- SR80-A2-5 (FD880)

- MAXIMUM SPINDLE TURNING SPEED:

- 1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 3.00 H.P. x 4P

- FACING HEAD MODEL:

- FD-880 (DOUBLE SLIDE TYPE)

- MAXIMUM LATERAL STROKE:

- 80.00 mm.

- MAXIMUM SPINDLE TURNING SPEED:

- SR80-A2-5 (FA812)

- MAXIMUM SPINDLE TURNING SPEED:

- 800.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 3.00 H.P. x 4P

- FACING HEAD MODEL:

- FA-812

- MAXIMUM LATERAL STROKE:

- 12.00 mm

- MAXIMUM SPINDLE TURNING SPEED:

- S80H-A2-5 (FA880)

- MAXIMUM SPINDLE TURNING SPEED:

- 2,500.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 3.00 H.P. x 4P

- FACING HEAD MODEL:

- FD-880 (DOUBLE SLIDE TYPE)

- MAXIMUM LATERAL STROKE:

- 80.00 mm.

- MAXIMUM SPINDLE TURNING SPEED:

- SR80H-A2-5 (FD-880)

- MAXIMUM SPINDLE TURNING SPEED:

- 2,500.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD:

- 3.00 H.P. x 4P

- FACING HEAD MODEL:

- FD-880 (DOUBLE SLIDE TYPE)

- MAXIMUM LATERAL STROKE:

- 80.00 mm.

- MAXIMUM SPINDLE TURNING SPEED:

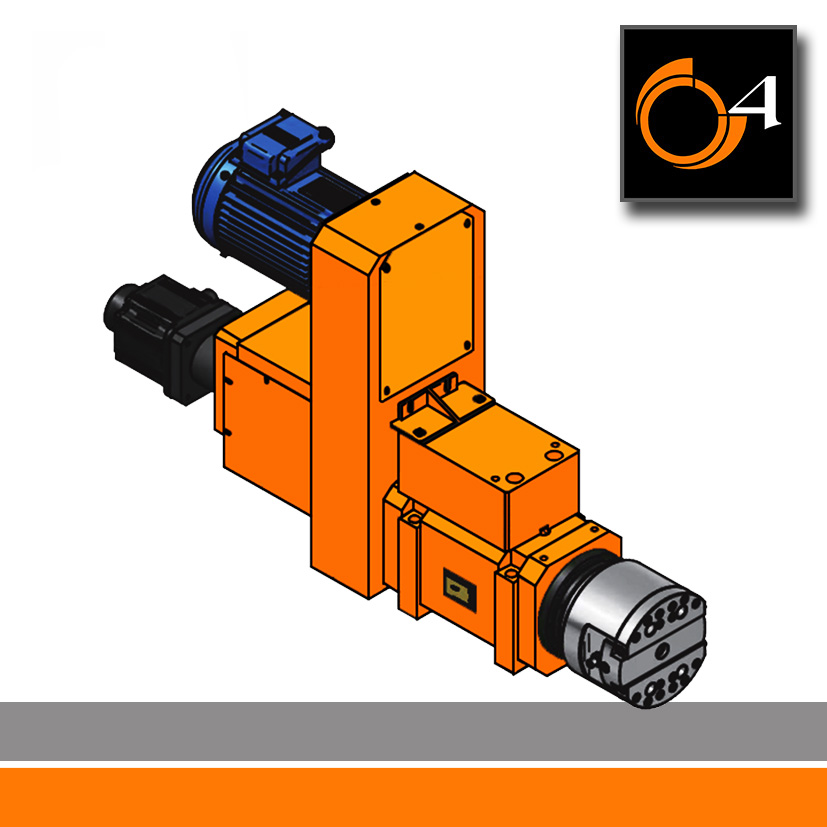

SERIE SSFSD

SERVO HEAD FOR FLANGE TYPE FACING (PATENT REGISTRY No. M510810)

- SSFSD09-120

- MAXIMUM SPINDLE STROKE: 120.00 mm.

- MAXIMUM SPINDLE TURNING SPEED: 1,600.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 3.00 H.P. x 4P

- FACING HEAD MODEL: FA-408

- MAXIMUM LATERAL STROKE: 8.00 mm.

- SSFSD11-120

- MAXIMUM SPINDLE STROKE: 120.00 mm.

- MAXIMUM SPINDLE TURNING SPEED: 1,600.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 3.00 H.P. x 4P

- FACING HEAD MODEL: FA-408

- MAXIMUM LATERAL STROKE: 8.00 mm.

- SSFSD12-150

- MAXIMUM SPINDLE STROKE: 150.00 mm.

- MAXIMUM SPINDLE TURNING SPEED: 1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 3.00 H.P. x 4P

- FACING HEAD MODEL: FA-610

- MAXIMUM LATERAL STROKE: 10.00 mm.

- SSFSD15-150

- MAXIMUM SPINDLE STROKE: 150.00 mm.

- MAXIMUM SPINDLE TURNING SPEED:1,200.00 r.p.m.

- MAXIMUM POWER HANDLED BY THE HEAD: 5.00 H.P. x 4P

- FACING HEAD MODEL: FA-610

- MAXIMUM LATERAL STROKE: 10.00 mm.