COMPACT SERVO SPINDLES manufactured by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, represent a significant evolution in the automation and high precision machining industry. Essential for motion control in advanced machinery systems, these devices offer a unique combination of efficiency, precision and versatility, making them critical components for a wide range of industrial applications.

The engineering excellence of 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE is evident in every aspect of its compact servo spindles. They are designed with a focus on durability, precision and energy efficiency. They incorporate cutting-edge technologies, such as high-precision bearings and advanced control systems, which allow exceptional levels of dynamic and static performance to be achieved, which is crucial for applications that require rapid speed changes and high precision.

These servo spindles play a vital role in numerous machining applications, from high-speed milling to high-precision turning and grinding operations. The responsiveness, precision, and ability to handle variable loads make them an ideal choice for production environments looking to improve the quality and efficiency of their machining processes.

The versatility of these devices is evident in their ability to integrate with modern control systems, giving manufacturers greater flexibility and control over machining operations. This integration capability makes them ideal for implementation in automated production lines and advanced manufacturing systems where precision and repeatability are critical.

In summary, compact servo spindles manufactured by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE are essential components for Automation and High Precision Machining. Their unmatched combination of dynamic performance, precision and adaptability makes them an irreplaceable choice for manufacturers and industrialists seeking to achieve superior levels of precision and efficiency in their machining and motion control operations.

The ELEMENTS that make up these lines are presented below:

ELEMENTS

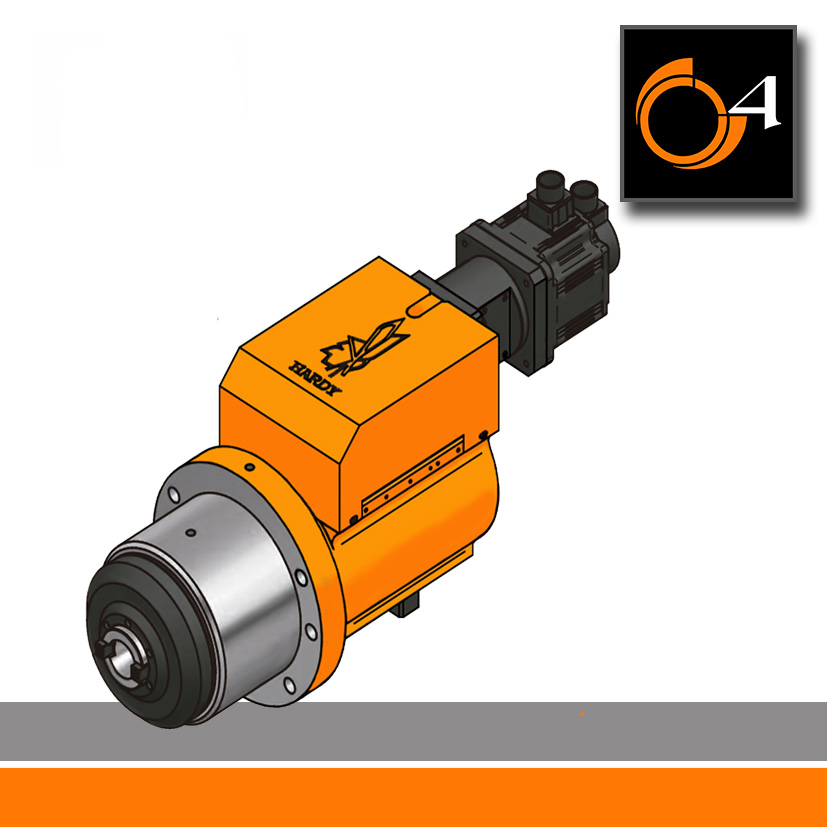

FMD SERIES

COMPACT SERVO SPINDLES FOR FLANGE TYPE TAPPING/DRILLING

- FMD-155

- MAXIMUM SPINDLE STROKE:

- 120.00 mm

- DRILLING CAPACITY:

- Ø30.00 mm

- MAXIMUM TAPPING CAPACITY:

- M24

- MAXIMUM SPEED:

- 2,500 r.p.m.

- MAXIMUM POWER:

- 3.7 Kw (5.0 H.P.)

- MAXIMUM SPINDLE STROKE:

*** Requiere De Un Sistema De Enfriamiento Por Aceite.

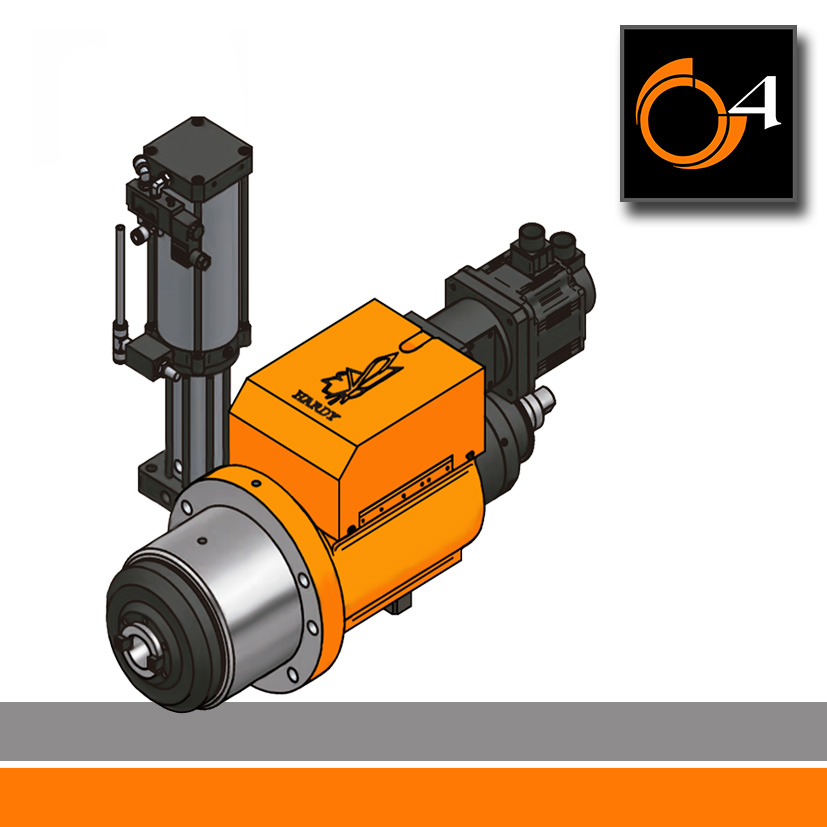

FMDC SERIES

COMPACT SERVO SPINDLES FOR FLANGE TYPE TAPPING/DRILLING WITH AUTOMATIC TOOL CHANGE SYSTEM

- FMDC-155W

- MAXIMUM SPINDLE STROKE:

- 120.00 mm

- DRILLING CAPACITY:

- Ø30.00 mm

- MAXIMUM TAPPING CAPACITY:

- M24

- MAXIMUM SPEED:

- 2,500.00 r.p.m.

- MAXIMUM POWER:

- 3.70 Kw (5.00 H.P.)

- MAXIMUM SPINDLE STROKE:

*** Requiere De Un Sistema De Enfriamiento Por Aceite.

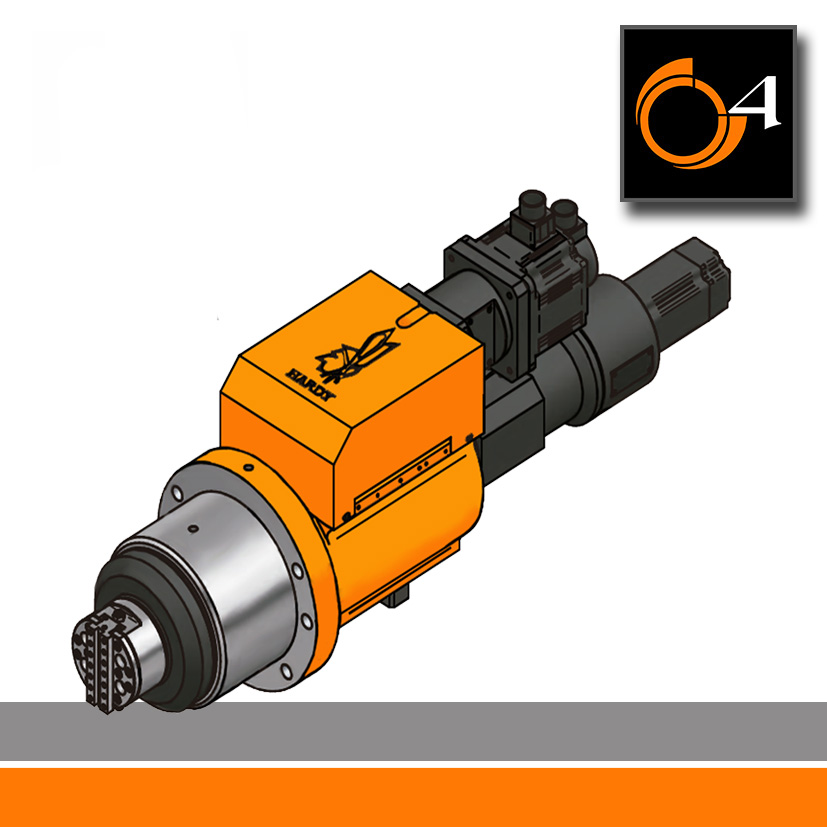

FMDM SERIES

COMPACT SERVO SPINDLE FOR FACING

- FMDM-155

- MAXIMUM SPINDLE STROKE:

- 120.00 mm

- MAXIMUM SPEED:

- 1,600.00 r.p.m.

- MAXIMUM POWER:

- 3.70 Kw ( 5.00 H.P.)

- CONFIGURATIONS:

- @220V/60Hz.

- @380V/60Hz.

- MAXIMUM SPINDLE STROKE:

*** Requiere De Un Sistema De Enfriamiento Por Aceite.

SM SERIES

COMPACT SERVO SPINDLES FOR MILLING/BORING/TACHING/DRILLING

- SM-45

- SPINDLE TYPE: NT30

- MAXIMUM SPEED: 2,500 r.p.m.

- MAXIMUM POWER: 1.5Kw (2.0 H.P.)

- SM-55

- SPINDLE TYPE: NT40

- MAXIMUM SPEED: 2,000 r.p.m.

- MAXIMUM POWER: 2.2Kw (3.0 H.P.)

- SM-80

- SPINDLE TYPE: NT50

- MAXIMUM SPEED: 1,500 r.p.m.

- MAXIMUM POWER: 3.7Kw (5.0 H.P.)

SM-H SERIES

COMPACT SERVO SPINDLES FOR HIGH SPEED MILLING/BORING/TACHING/DRILLING

- SM-45H

- SPINDLE TYPE: NT30

- MAXIMUM SPEED: 8,000 r.p.m.

- MAXIMUM POWER: 1.5Kw (2.0 H.P.)

- SM-55H

- SPINDLE TYPE: NT40

- MAXIMUM SPEED: 6,000 r.p.m.

- MAXIMUM POWER: 2.2Kw (3.0 H.P.)

- SM-80H

- SPINDLE TYPE: NT50

- MAXIMUM SPEED: 2,500 r.p.m.

- MAXIMUM POWER: 3.7Kw (5.0 H.P.)