The Tapping and Drilling heads manufactured by Hann Kuen Machinery & Hardware, Co., Ltd®., and marketed by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, represent an innovative solution in the manufacturing industry. high precision manufacturing.

Designed with the latest technology and a meticulous focus on quality, these heads offer exceptional performance in a variety of machining applications.

4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, is recognized for its commitment to excellence in the manufacturing of machining equipment, and Taping and Drilling heads are no exception. Each head is produced from premium materials and undergoes rigorous quality testing to ensure high-precision, reliable operation.

The tapping and drilling heads manufactured by Hann Kuen Machinery & Hardware, Co., Ltd®., and marketed by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, stand out for their versatility, which allows Allows operators to carry out a wide range of machining operations with a single tool.

This not only simplifies the production process, but also saves time and costs associated with constantly changing tools.

The partnership between Hann Kuen Machinery & Hardware, Co., Ltd®., and 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, ensures that these heads are not only produced to the highest standards, but They are also supported by a team committed to providing exceptional service and specialized technical support. Additionally, the availability of these heads through 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, facilitates their access to a wide range of manufacturing industries, providing efficient and reliable solutions to modern machining challenges.

In summary, the Tapping and Drilling heads manufactured by Hann Kuen Machinery & Hardware, Co., Ltd.), and marketed by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware BRANCH OFFICE, constitute an outstanding option for demanding machining operations. Its combination of quality, versatility and support ensures that customers can successfully meet the most demanding production challenges while maintaining high standards of precision and efficiency.

The Solutions Designed to perform TAPPING and DRILLING PROCESSES simultaneously, which we have, are listed below:

ELEMENTS

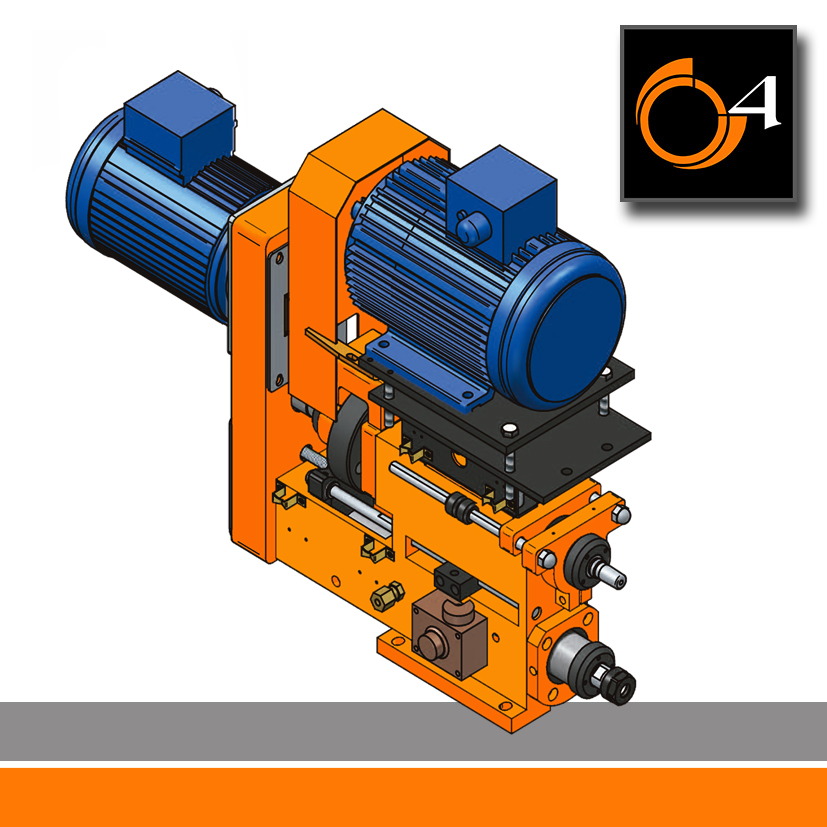

D51N SERIES

DOUBLE HEAD FOR SIMULTANEOUS TAPPING / DRILLING PROCESS

- DRILLING

- Velocidad Máxima: 5,000 r.p.m.

- Carrera Máxima Del Husillo: 85.00 mm.

- Capacidad Máxima De Perforado: 13.00 mm.

- TAPPING

- Carrera Máxima Del Husillo: 65.00 mm

- Capacidad Máxima De Machueleado: M12

** DESCARGA DE PDF – SERIE D51N

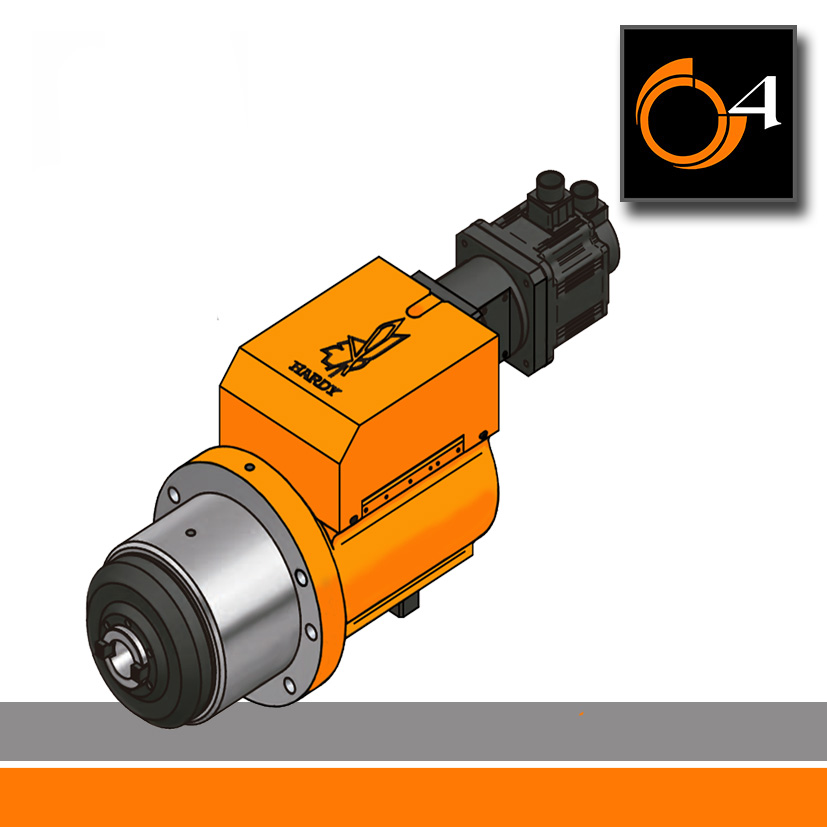

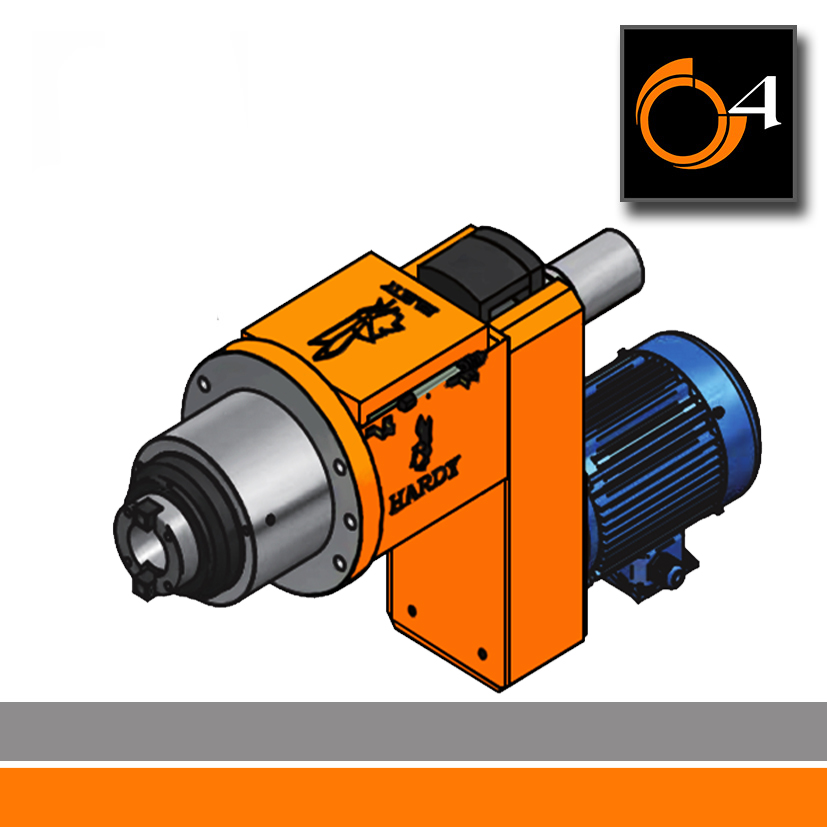

FMD SERIES

COMPACT SERVO SPINDLE FOR TAPPING / DRILLING

The spindle unit with built-in asynchronous motor of the FMD155 units is designed for drilling and tapping applications. Power is transmitted via a class C5 ball screw and servo motor for precise positioning. The design of this product provides space savings and increases your efficiency and productivity. The spindle tip accuracy is less than 0.003mm and the maximum drilling capacity is up to 30mm (S45C).

- FMD-155

- Carrera Máxima: 120.00 mm

- Capacidad De Perforado: 30.00 mm

- Capacidad De Machueleado: M24

- Velocidad Máxima: 2,500.00 r.p.m

- Potencia Máxima: 3.7 Kw

*** REQUIRES OIL COOLING SYSTEM

** DESCARGA DE PDF – SERIE FMD-155

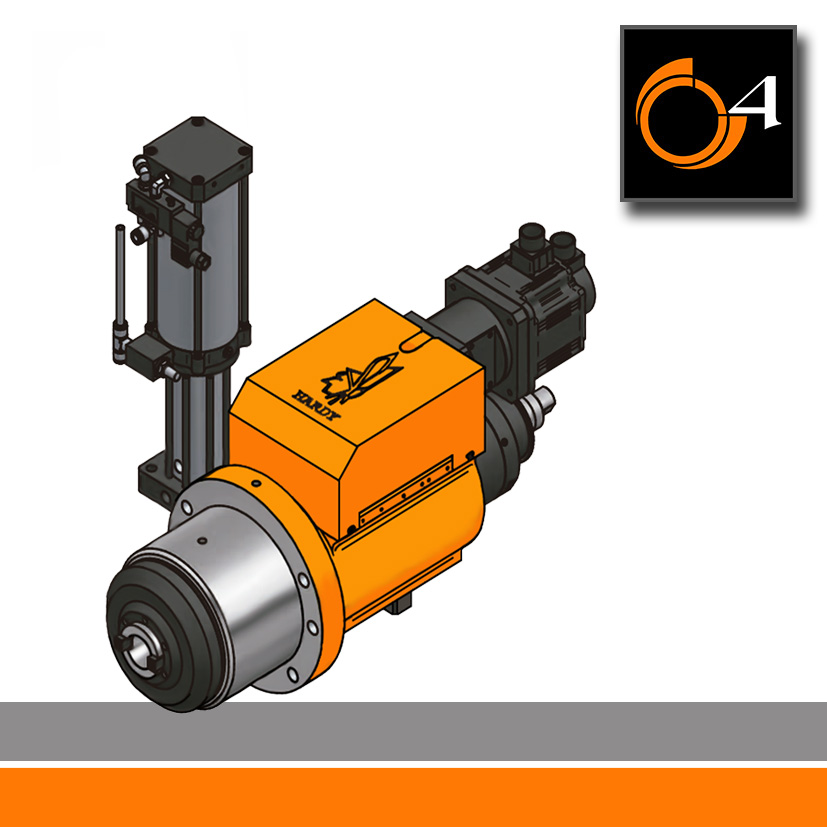

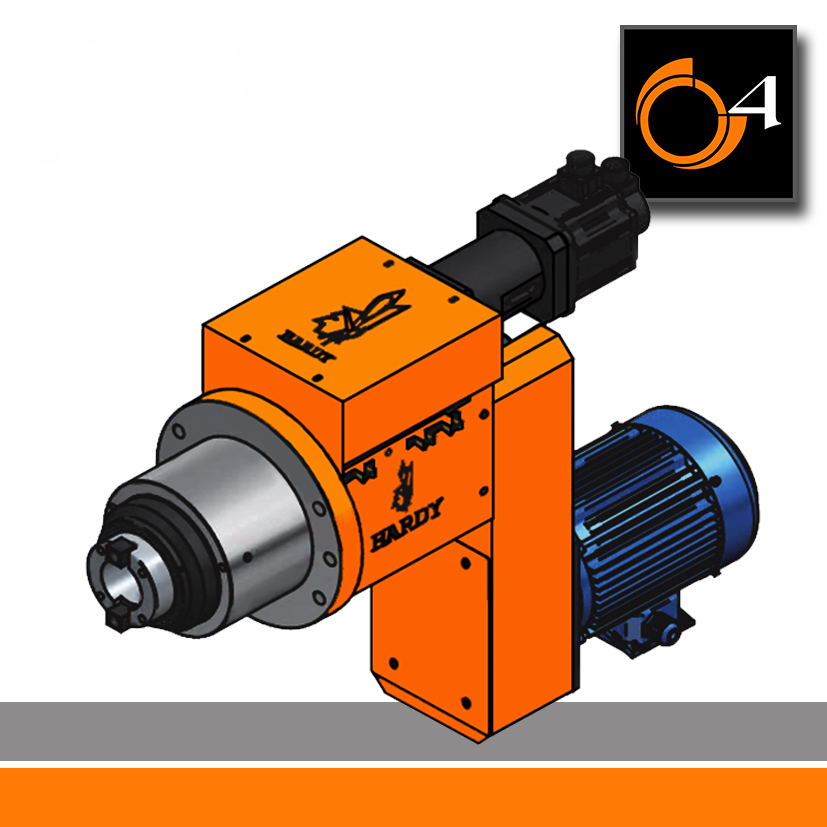

FMDC SERIES

COMPACT SERVO SPINDLE FOR TAPPING / DRILLING WITH TOOL CHANGE SYSTEM

The built-in asynchronous motor spindle unit with automatic tool changer FMDC155W from 4ManPro® is designed for central coolant drilling and tapping in complex applications. Power is transmitted via a class C5 ball screw and servo motor for precise positioning. The design of this product provides space savings and increases your efficiency and productivity. The spindle tip accuracy is less than 0.003mm and the maximum drilling capacity is up to 30mm (S45C).

- FMDC-155W

- Carrera Máxima: 120.00 mm

- Capacidad De Perforado: 30.00 mm

- Capacidad De Machueleado: M24

- Velocidad Máxima: 2,500.00 r.p.m

- Potencia Máxima: 3.7 Kw

*** REQUIRES OIL COOLING SYSTEM

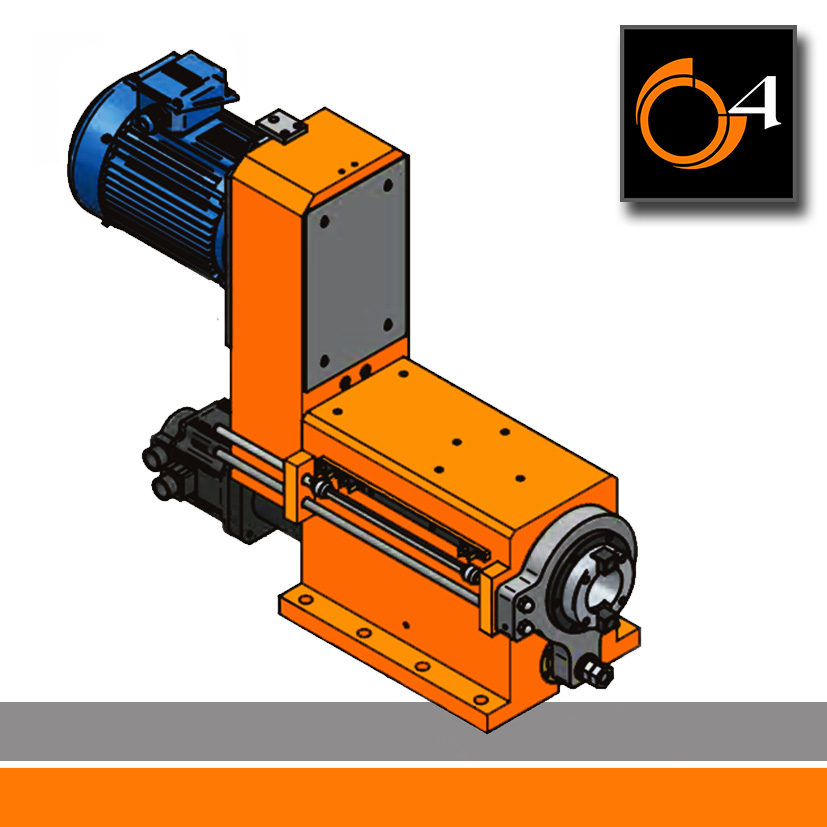

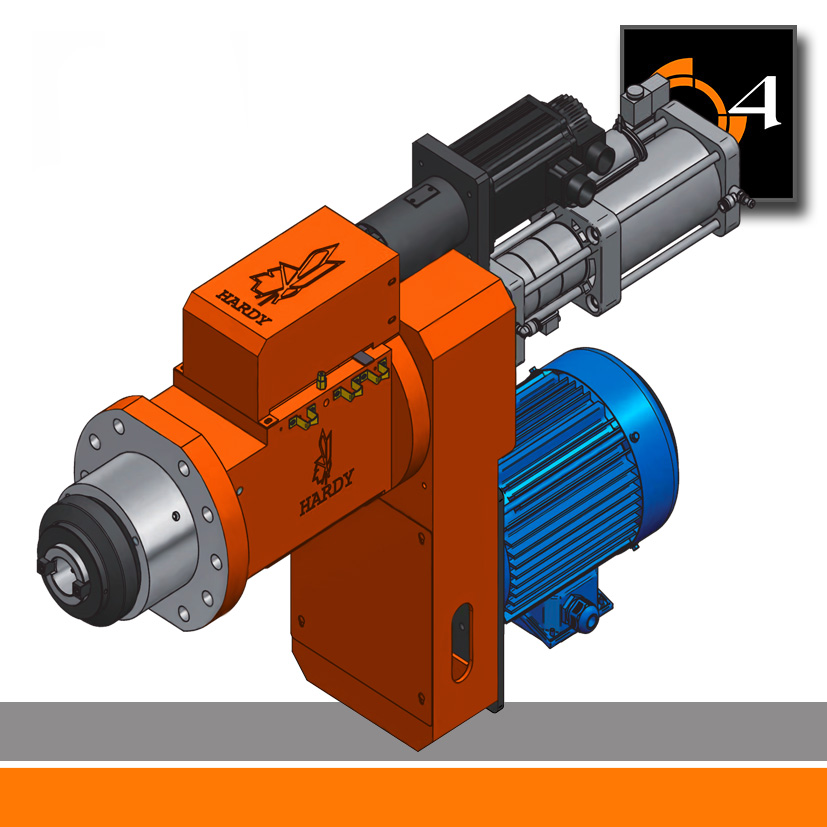

SFHD SERIES

FLANGE TYPE DRILLING HEAD

SFHD Series Flange Drilling Heads are designed with hydraulic cylinder feed.

The precision of the spindle tip is strictly less than 0.003mm and the maximum drilling capacity is up to 25.00mm (S45C).

This unit allows you to carry out all types of Machining Processes such as Drilling, Threading, Chamfering, Reaming and Countersinking.

The maximum drilling capacity according to its capacities is Ø16mm., Ø25mm., Ø35mm., Ø35mm. & Ø50mm., with Maximum Strokes of 100.00mm, 120.00 mm & 150.00 mm. And Maximum Working Power of 1 H.P., 2 H.P., 3 H.P. & 5 H.P.

It is possible to make adjustments to both the Maximum Stroke and the Maximum Power of the equipment by request of the user.

SFSD SERIES

SERVO HEAD FOR FLANGE TYPE TAPPING/DRILLING

SFSD Series Flange Type Servo Tapping/Drilling Heads are designed with servo feeding with C5 grade ball screw and servo motor for rotary trunnion machines.

The precision of the spindle tip is strictly less than 0.003mm.

This unit allows you to carry out all types of Machining Processes such as Drilling, Threading, Chamfering, Reaming and Countersinking.

The maximum drilling capacity according to its capacities are Ø16 mm., Ø25 mm., Ø35 mm., Ø35 mm. & Ø50mm., with Maximum Strokes of 100.mm, 120.00 mm & 150.00 mm. And Maximum Working Power of 1 H.P., 2 H.P., 3 H.P. & 5 H.P.

It is possible to make adjustments to both the Maximum Stroke and the Maximum Power of the equipment by request of the user.

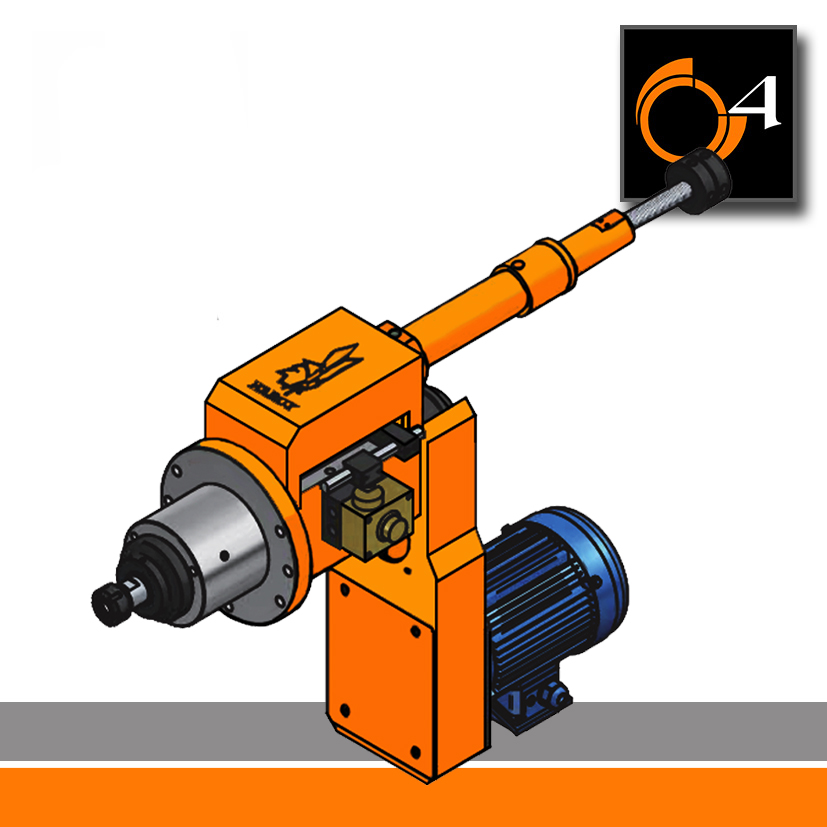

SFST SERIES

TACHING HEAD WITH SCREW TRANSMISSION FLANGE TYPE PATTERN

The Flange Type Tapping Heads with Pattern Screw Transmission is designed with lead screw transmission, automatic thread cutting support and floating male chuck.

The maximum threading capacity according to their capacities are M12, M30, M35, M45 & M50, with Maximum Strokes of 50.00 mm, 65.00 mm, 85.00 mm & 90.00 mm. And Maximum Working Power of ½ H.P., 1 H.P. & 2 H.P.

It is possible to make adjustments to both the Maximum Stroke and the Maximum Power of the equipment by request of the user.

Likewise, the Pitch of the Pattern Screw must be determined by the user.

SSFC SERIES

SERVO HEAD FOR TAPPING / DRILLING WITH FLANGE TYPE AUTOMATIC TOOL CHANGE SYSTEM

- SSFC11-120M

- Capacidad Máxima De Perforado:

- Ø35 mm

- Carrera Máxima:

- 120.00 mm

- Velocidad Máxima:

- 2,200 r.p.m.

- Potencia Máxima:

- 3 H.p. x 4P (2.2kW)***

- Capacidad Máxima De Perforado:

*** It can be configured with a 5 H.P. motor. x 4P (3.7Kw.) At Customer’s Request.

- SSFC11H-120M

- Capacidad Máxima De Perforado:

- Ø35 mm

- Carrera Máxima:

- 120.00 mm

- Velocidad Máxima:

- 6,000 r.p.m.

- Potencia Máxima:

- 3 H.p. x 4P (2.2kW)***

- Capacidad Máxima De Perforado:

*** It can be configured with a 5 H.P. motor. x 4P (3.7Kw.) At Customer’s Request.

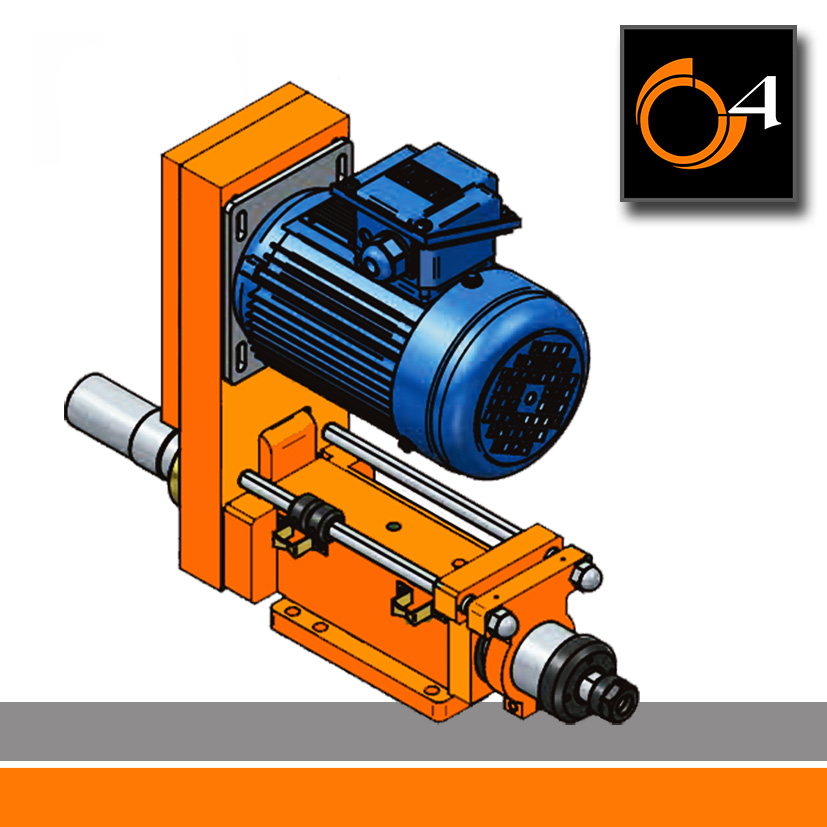

SSD SERIES

SERVO HEADS FOR TAPPING/DRILLING

SSD Series Servo Spindle Heads for Tapping/Drilling are designed with servo feeding by C5 grade ball screw and servo motor, the precision of spindle tip is strictly less than 0.003mm.

The Maximum Drilling Capacity of the Servo Heads are Ø6mm @10,000r.p.m., Ø13mm @5,000r.p.m., Ø16mm @3,500r.p.m.~@10,000r.p.m., Ø25mm @3,000r.p.m.~@8,000r.p.m., Ø35mm @2,000r.p.m.~@6,000r.p.m. & Ø50 @1,600 r.p.m.~@4,000 r.p.m. (S45C).

The SSD Series CNC Servo Heads allow you to perform all types of machining applications such as drilling, threading, chamfering, reaming and countersinking.

ST SERIES

TAPPING HEADS

ST Series tapping spindle heads are designed with lead gauge screw drive, automatic thread cutting bracket and floating male chuck.

The maximum threading capacity according to their capacities are M6, M12, M30 & M45, with Maximum Strokes of 50.00 mm, 65.00 mm, 85.00 mm & 90.00 mm. And Maximum Working Power of ½ H.P., 1 H.P. & 2 H.P.

It is possible to make adjustments to both the Maximum Stroke and the Maximum Power of the equipment by request of the user.

Likewise, the Pattern Screw Pitch must be requested by the user.